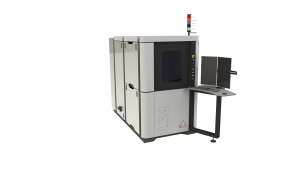

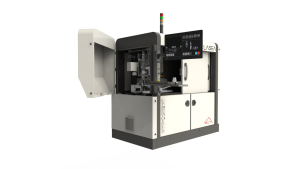

The Lasea GEODE is a high-performance 5-axis ultrafast laser micromachining system designed for complex 3D processing, precision engineering, and industrial scalability. Built to deliver maximum accuracy and repeatability, the GEODE combines cutting-edge optics, precision motion control, and advanced software to achieve outstanding results across diverse materials.

Using femtosecond laser technology, the GEODE enables non-thermal ablation, ensuring smooth edges, no burr formation, and minimal heat-affected zones. This capability makes it ideal for processing metals, ceramics, polymers, and glass with micron-level precision. Its dynamic 5-axis architecture allows full control over the laser beam’s orientation, enabling machining on curved, inclined, and complex geometries.

Engineered for industrial reliability, the system features real-time monitoring, automated alignment, and integrated vision control, guaranteeing consistent, high-quality output. The GEODE’s modular design supports easy integration into automated manufacturing lines and R&D setups, delivering both flexibility and throughput.

Perfect for applications in aerospace, medical devices, luxury watchmaking, and semiconductor production, the GEODE sets the standard in precision 3D laser micromachining.

Standard equipment (Quartz + Geode Combination):

- Nanosecond laser, femtosecond laser or welding laser in IR

- Mechanical Z axis of 350mm or 550mm

- User training

- 160mm lens (other lenses possible as options)

- LENS control software (under Windows)

Services / Options :

- Mechanical XY axes 200mm x 200mm

- Geode palletizer

- Fume extraction system

- Gas nozzle

- LASERCAM proprietary software (positioning by video assistance or through the scanner)

- Up to 3 physical cameras and as many virtual cameras as needed

- Service contract